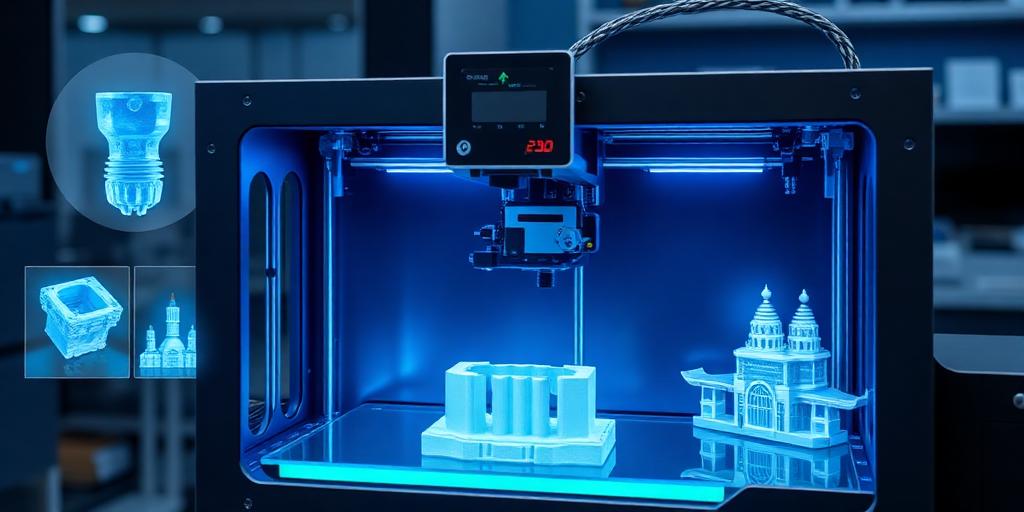

The landscape of global industry is in a perpetual state of evolution, driven by technological breakthroughs that redefine manufacturing, design, and supply chains. Among these advancements, additive manufacturing, commonly known as 3D printing, stands as a transformative force with profound potential across a myriad of sectors. Far from being a mere prototyping tool, the 3D Printing Potential now extends to mass customization, on-demand production, and the creation of highly complex geometries previously unattainable.

The Foundational Shift of Additive Manufacturing

At its core, 3D printing constructs three-dimensional objects layer by layer from a digital design. This method offers distinct advantages over traditional subtractive manufacturing processes, such as machining, by significantly reducing material waste, enabling intricate designs, and accelerating product development cycles. The impact of 3D printing on manufacturing processes is not incremental; it represents a fundamental paradigm shift toward efficiency, innovation, and adaptability.

Industrial 3D Printing Applications Across Key Sectors

The widespread adoption of 3D printing technology is a testament to its versatility. Its industrial 3D printing applications are reshaping operational norms and opening new avenues for product creation.

Healthcare and Medical Devices

In the medical field, 3D printing is revolutionizing patient care. It enables the creation of highly personalized prosthetics and orthotics that precisely fit individual anatomies, improving comfort and functionality. Surgical guides, custom implants (such as hip and knee replacements), and even bioprinted tissues for research are becoming increasingly common. This personalization capability represents a significant leap forward, offering tailored solutions that enhance clinical outcomes and quality of life.

Aerospace and Automotive

For industries where weight reduction and structural integrity are paramount, 3D printing offers immense value. Aerospace manufacturers utilize additive manufacturing to produce lightweight, complex components like engine brackets and air ducts, which can lead to substantial fuel savings and enhanced performance. Similarly, in the automotive sector, 3D printing facilitates rapid prototyping of new parts, production of bespoke components for high-performance vehicles, and the development of tooling and fixtures, shortening design cycles and enabling greater design freedom.

Construction and Architecture

The construction industry is exploring 3D printing for building entire structures, from small homes to large-scale infrastructure. This approach offers the potential for faster construction times, reduced labor costs, and the ability to utilize sustainable or recycled materials. Architectural firms also leverage 3D printing for creating intricate, detailed models that accurately represent complex designs, aiding visualization and client communication.

Consumer Goods and Retail

From personalized footwear to custom jewelry and intricate decorative items, 3D printing empowers consumer-driven customization. This allows brands to offer unique products tailored to individual preferences, reducing inventory waste and enabling on-demand production models. The agility offered by this technology aligns perfectly with evolving consumer expectations for bespoke goods.

Education and Research

Universities and research institutions are at the forefront of exploring the future of 3D printing technology. They utilize 3D printers as essential tools for teaching design principles, conducting material science experiments, and developing cutting-edge applications, fostering the next generation of innovators and pushing the boundaries of what's possible.

The Transformative Impact of 3D Printing on Business Models

The transformative impact of 3D printing extends beyond product creation to influence entire business models. It facilitates localized production, reducing reliance on complex global supply chains. Furthermore, the ability to produce on demand minimizes warehousing costs and mitigates the risks associated with overproduction. This shift towards more agile and responsive manufacturing systems holds significant economic implications.

Overcoming Challenges and Looking Ahead

While the benefits of additive manufacturing are clear, challenges such as material limitations, scalability for mass production, and initial equipment costs remain. However, ongoing research and development are steadily addressing these hurdles, leading to innovations in material science, faster printing speeds, and more accessible printer technologies.

In conclusion, 3D printing is not merely a niche technology; it is a foundational component of the next industrial revolution. Its capacity for innovation, customization, and efficiency positions it as a critical enabler for industries worldwide, promising a future where manufacturing is more responsive, sustainable, and capable of creating products precisely tailored to individual needs.